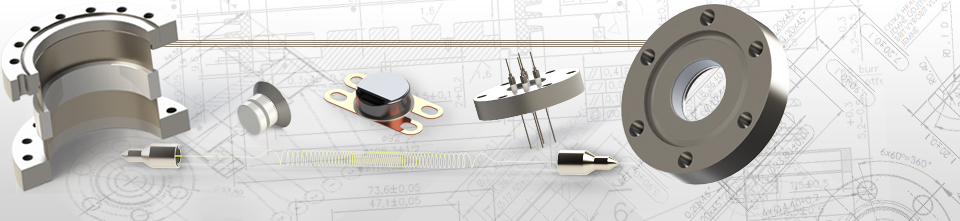

Vacuum Feedthroughs

The efficient coupling of energy in vacuum systems requires so-called vacuum feedthroughs. These are connected by flange systems which of course have to be vacuum-tight. Generally stainless steel is used for the flanges and either nickel-iron alloys or non-ferromagnetic copper and its alloys for the membranes. The electrical isolation is achieved with aluminium oxide ceramics. The results are throughputs which are carefully matched to your system, contributing to the reliability, quality and efficiency of your processes. Alumina Systems produces precise vacuum throughputs in every size according to your specific needs, utilising FEM computer-aided design to make reliable predictive statements about the potential design. Alternative material choices, production methods and component matching can be elaborated and evaluated. In the end it is the computer numerical data package on stress distribution, break potential and solderability which determines the overall suitability of your design. Alumina systems also offers a standard range of components for vacuum isolation for the range up to 10kV and 80A.

Within the standard range, three designs are available: weld adapters in nickel-iron alloy or stainless steel flanges in ISO (KF-flange) and ConFlat (CF flange) variants. In combination with the chosen flange, the feedthroughs can be offered as single or multiple components. A building block system enables non-standard conductor lengths to be offered (on enquiry). Any vacuum feedthrough from the standard range can usually be despatched within two weeks; and orders from one single unit upwards are acceptable.

Feedthroughs

SK 280 10 Feedthrough HT - 1,25´´

SK 280 10 Feedthough HT - 1,25´´

Your price: €157.50 €154.67